Water is the main fluid used in hydraulic fracturing to produce natural gas or crude oil. Managing water for the vast southeastern US Permian Basin fracking operation is a crucial element of the production process that contributes about 45% of the total USA crude oil and 20% of its natural gas. Operators and water management companies have built thousands of lined lagoons or pits to hold produced and fresh water used or re-used in the process. Understanding the capacity and operating volume of the pits is an important element of the water management requirement. As the pits are small and very numerous, a USV survey program is ideal. The equipment can be easily transported from site to site; deployment and recovery can be undertaken safely and quickly.

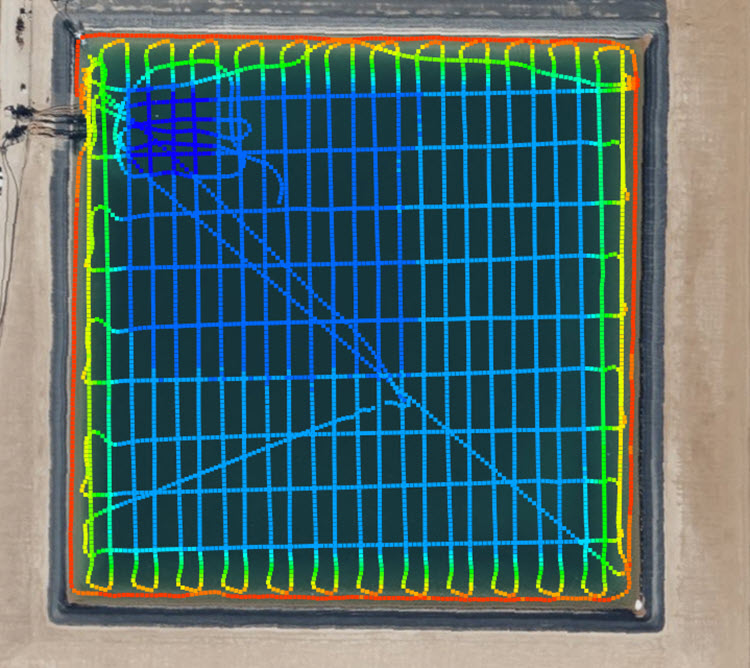

Select Water Solutions have been at the forefront of using USVs for oilfield surveys since 2012. For a new survey project planned for 2026, a new CEE-USV package was brought into the Permian Basin in Midland, TX. The use of an autopilot USV allows precise and consistent survey lines for the accurate identification of the pit slopes right to the edge of the water. A manual RTK elevation survey can be conducted to mark the exact top / boundary of the pit. A Hemisphere S631 base station is set up at each pit, to provide a local elevation benchmark with the CEE-USV and the land survey rover receiving real time corrections over a radio link.

Using Hydromagic software, the RAW data are edited and the depth matrix (TIN model) is generated to show the volume in the pit at the time of the survey. With the boat operating on autopilot, instead of the operator having to view the data in real time to navigate the boat as was required on the old system, the land survey tasks may be conducted simultaneously – saving time on each pit survey.

In the next stage of the data processing, the elevation of the pit boundary is introduced to allow extrapolation of the surveyed area to the spill-over level of the pit. With this additional data, the total volume of the pit can be calculated in Hydromagic – not just the water area.

A stage-volume curve can then be generated to calibrate level indicator instrumentation in terms of pit volume. With this survey complete, further trips to the pit are not required as water level alone can be used to monitor the available water volume.