Mine tailings operators often need to report the volume of water in their tailings impoundments regularly or periodically for regulatory purposes; many sites also use tailings water volumes in site water balance engineering calculations. The latter might need fairly routine monitoring of the water pool. Unmanned boats (USVs) are an ideal method to survey most tailings impoundments, as personnel safety is maximized and the tailings pool dimensions are usually in the desirable range for USV surveys. In late 2022, CEE USA were requested to conduct a one-off survey of a tailings pond in the USA using the CEE-USV™ unmanned system. With a pool size of about 4000 x 2500ft (1.2 x 0.8km) the area was fairly large. A drone image was available from several weeks before the survey, however owing to the nature of tailings beaches it is difficult to ascertain the true extent of the “navigable” water around the edges of the pool where tailings are deposited. So only a very rough idea of the survey boundary was available before the job. From this, it was determined that 100ft spacing for survey lines would be appropriate. Hydromagic acquisition software was used for data collection.

In common with many mines, the site operated a historic local mine grid and data XY output would need to line up with mine survey data all collected in the local grid coodinate system. To do this, a pair of points around the tailings impoundment in the NAD83 / State Plane projection were provided and the corresponding local grid coordinates were calculated in the site’s USV Propeller program. With these four points, Hydromagic was able to generate the site grid parameters automatically.

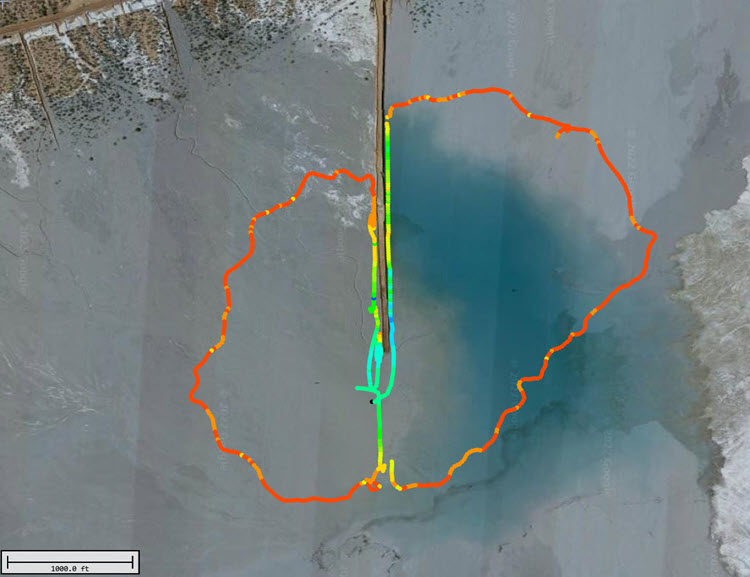

When setting up the survey, a shore control station was first established where the distance to the CEE-USV™ was within the safe operating range for the medium range antenna set in use (under about 3000ft). The USV was configured with the CEE-PILOT™ robotic control autopilot so very little actual manual driving would be needed. Upon launching the boat, the USV was first driven around the perimeter of the pool close to the beach (but not too close!). With the real time shore navigation display showing the boat track and depth, the operator simply kept the boat at about the 1-1.5ft (30-45cm) contour while driving around the perimeter. Owing to the gentle gradients in tailings impoundments and the ability to drive the CEE-USV™ in just a few inches of water, the safety margin is still fairly high at 1ft depth. Driving the USV up onto the beach with no method of retrieval on site would not be a good situation!

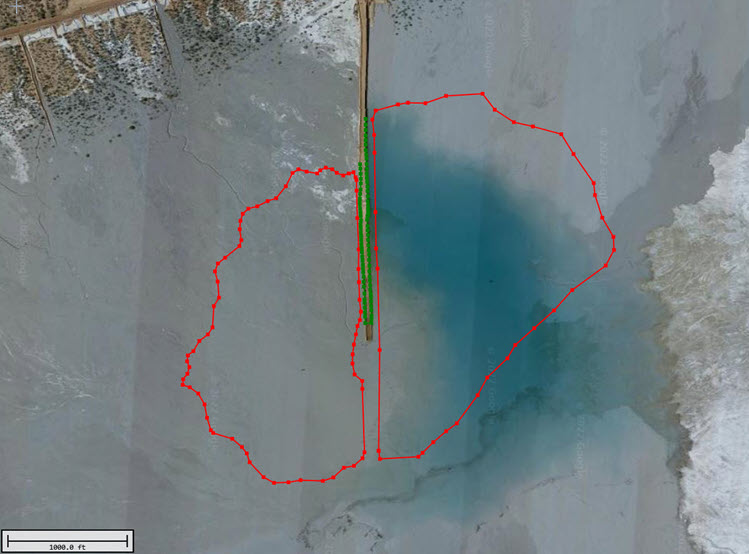

With the USV having traced the extent of the survey, next a boundary was drawn to match this outline.

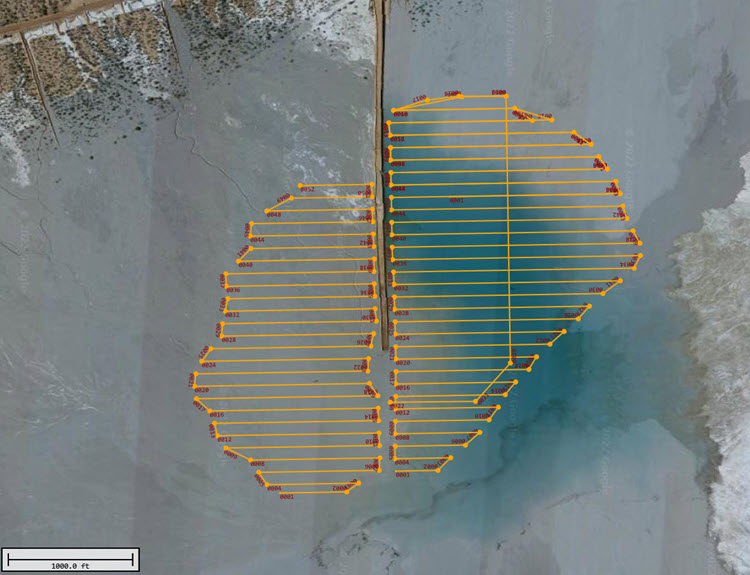

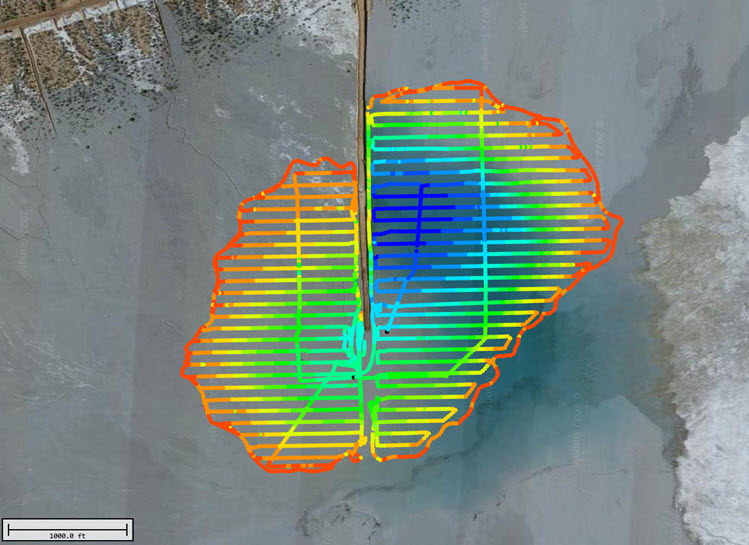

This boundary was only required to allow the generation of an autopilot route plan. With the selection of 100ft line spacing, the USV’s route was planned in two segments – East / West.

With the route loaded in Hydromagic, all that was then required was the press of the “Transfer Route” button to send the waypoints to the on-board autopilot. With the USV switched to AUTO mode the survey started. As is common for tailings surveys in mountainous areas, wind was moderate so the autopilot vastly improved the raw data line tracks versus a manually operated survey in these conditions. Operating manually would otherwise have required continuous attention to stay on the line. As it was, the operator and site contacts could just sit in the truck watching the data and wait for the USV to complete the 18 mile journey around the route.

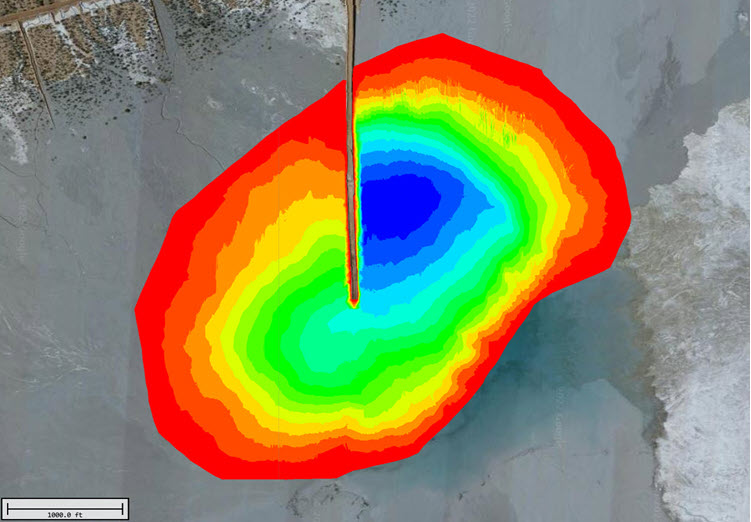

Unedited data above was very clean – typical for CEE-USV™ data on tailings impoundments and total survey duration was about 6.5 hours. From the drone images, an estimate of the waters edge was generated and a second boundary drawn around the survey that marked the “zero depth” point. This boundary was used to generate a matrix of XYZ points to represent the entire water pool. From this matrix, estimated total water volume was calculated. On the day of the survey, the water level was determined by a static GNSS shot with a site rover. This elevation was used to shift the raw depth data to absolute elevations for incorporation into site surveys.